Skip to content

- Always use (a) dust collector, (b) safety glasses, and (c) hearing protection. If necessary, use a (d) N95 dust mask.

- Do not touch tools after cutting, friction may cause high temperatures.

- You must sit by the CNC for the duration of your cut and know where the fire extinguisher is located. Friction during cutting may cause fire.

- Turn on the dust collector in the backroom, and open the dust collector’s tube sliding plate above the CNC machine.

- Do not put hands or any objects near the machine while it is operating.

- If your operation will produce a lot of dust, please use a vacuum but be careful of spindle and watch its movements. You don’t want to hit it!!

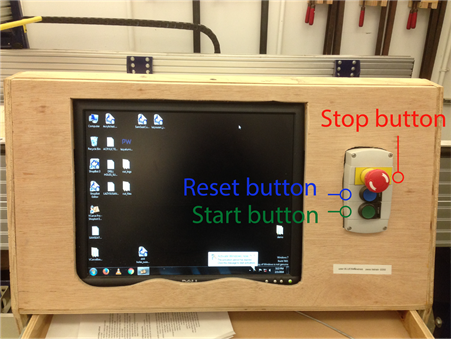

- Emergency stop — There are three red emergency stop buttons that will stop the machine instantly. Locate where they are in case of an emergency. Additionally, clicking the mouse button while the machine is sending data will stop all motors.

- The ShopBot software doesn’t like doing multiple tasks, so always make sure to close the keypad window before doing another ShopBot operation.

- When first starting the machine, don’t forget to push the blue reset button. Read more details in How to Operate the Machine chapter.

- If you pause the machine for any reason be sure to start the spindle before resuming your cut.